Proper kitting is a critical aspect of assembly operations in manufacturing settings. It involves the organized gathering and packaging of all the necessary components and materials required for the assembly process. Efficient kitting plays a crucial role in streamlining production workflows, reducing downtime, minimizing errors, and improving overall productivity. In this article, we will explore the significance of proper kitting and its impact on assembly operations.

In the bustling world of Texas warehousing, where precision and efficiency are paramount, proper kitting in assembly operations plays a pivotal role. From the vibrant warehouses in Houston to the strategically positioned distribution centers in Dallas, the practice of kitting ensures that components are organized, assembled, and prepared for seamless production. This article explores the importance of proper kitting in assembly operations, emphasizing the keywords associated with warehousing and logistics in Texas.

Table of Contents

Enhanced Efficiency and Time Savings:

Proper kitting ensures that all the required components are readily available and grouped together for each assembly task. This saves valuable time that would otherwise be spent searching for materials or waiting for deliveries. By having all the necessary items conveniently packaged and easily accessible, assembly personnel can focus on the task at hand without interruptions, leading to improved efficiency and faster production cycles.

Reduced Risk of Errors:

Kitting helps eliminate the risk of missing or incorrect components during the assembly process. With each kit containing the exact parts needed for a specific task, the likelihood of assembly errors or mix-ups is significantly reduced. This leads to higher product quality and minimizes the need for rework, which can be time-consuming and costly.

Inventory Management:

Proper kitting is closely tied to effective inventory management. By organizing and packaging materials in kits, it becomes easier to track and control inventory levels. This allows manufacturers to have a clear overview of the materials needed for production, reducing excess stock and the risk of running out of crucial components.

Flexibility and Scalability:

In assembly operations that require producing multiple product variants or customization, kitting allows for greater flexibility. Different kits can be prepared for various product configurations, enabling a smoother transition between assembly tasks and reducing setup time. Additionally, as production volume scales, well-organized kitting processes can accommodate increased demands more efficiently.

Streamlining Assembly Processes

- Optimizing Component Organization:Proper kitting involves the organized grouping of components and materials needed for specific assembly tasks. Warehouses in Texas, including those in Houston and Dallas, benefit from streamlined assembly processes as components are pre-selected, reducing search times and minimizing disruptions.

- Reducing Downtime:Efficient kitting minimizes downtime during assembly operations. When components are readily available and well-organized, assembly teams can focus on the task at hand without interruptions. This reduction in downtime contributes to increased productivity and faster production cycles.

Enhancing Accuracy and Precision

- Ensuring Correct Component Selection: Kitting ensures the correct selection of components needed for a particular assembly. In Texas warehouses, precision is crucial, and proper kitting minimizes the risk of errors in component selection, leading to accurate and high-quality finished products.

- Minimizing Errors in Assembly: Components organized through proper kitting contribute to error reduction during assembly. Texas warehouses benefit from a decrease in mistakes, rework, and defects, resulting in improved overall product quality and customer satisfaction.

Efficient Resource Utilization

- Reducing Excess Inventory: Proper kitting enables warehouses in Texas to manage inventory more efficiently. By assembling components in predefined kits, excess inventory is minimized, reducing holding costs and optimizing resource utilization.

- Enhancing Space Efficiency: Kitting allows for efficient use of warehouse space. Warehouses in Houston and Dallas can organize kits in a way that maximizes space utilization, leading to a well-organized and visually clear environment that facilitates efficient assembly operations.

Meeting Customer Demands

- Facilitating Faster Order Fulfillment: In the competitive landscape of Texas warehousing, meeting customer demands for quick order fulfillment is crucial. Proper kitting ensures that components are readily available, facilitating faster assembly and order processing.

- Supporting Customization: Proper kitting is especially valuable in environments where customization is a key requirement. Warehouses in Texas can organize kits tailored to specific customer orders, allowing for flexibility and responsiveness to diverse customer needs.

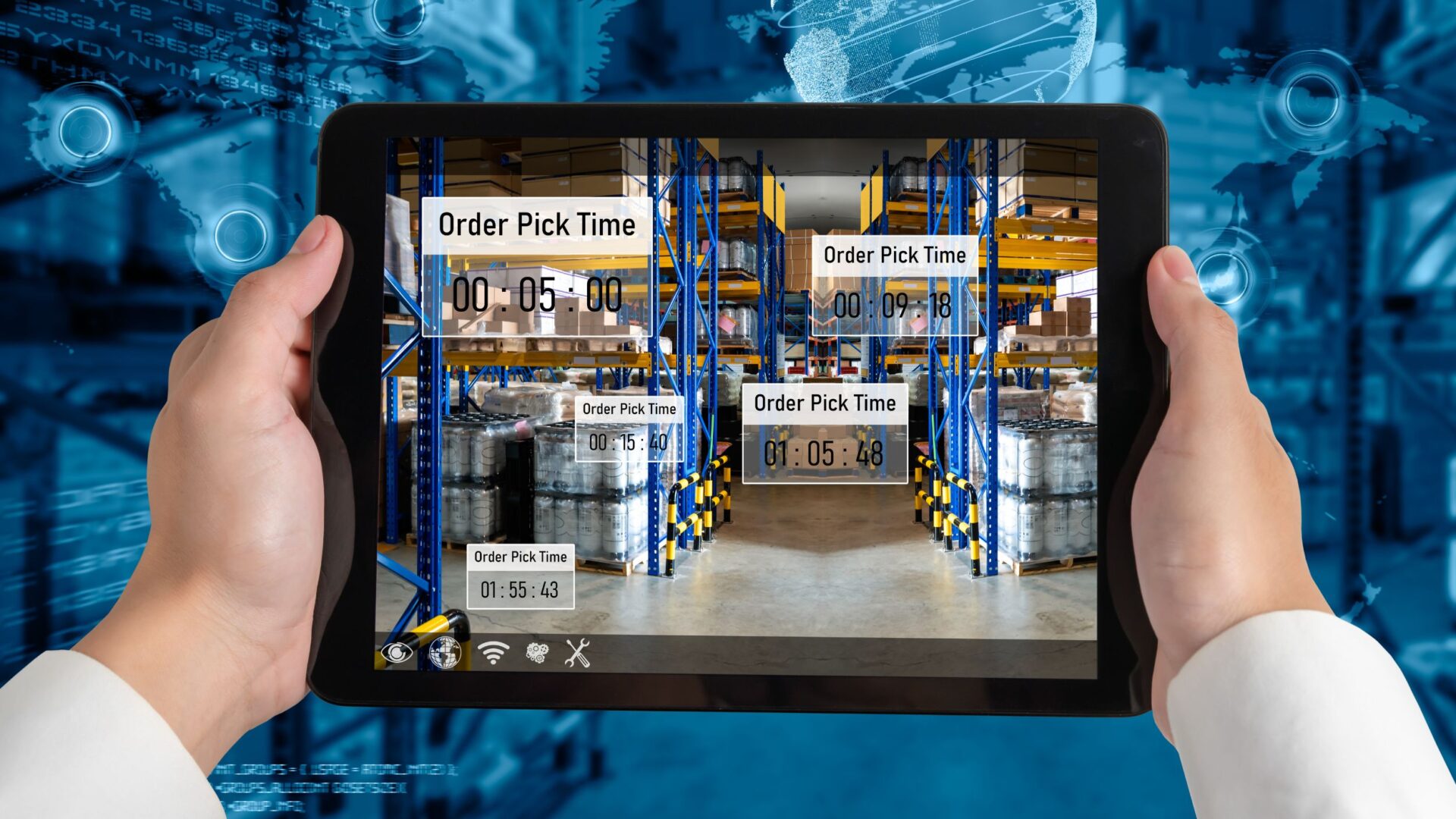

The Role of Technology in Kitting

- Utilizing Warehouse Management Systems (WMS): Warehouses in Texas leverage advanced technologies, including Warehouse Management Systems (WMS), to enhance kitting processes. WMS facilitates real-time tracking, monitoring, and optimization of kitting operations, contributing to overall efficiency.

- Incorporating Automation: Automation plays a significant role in kitting processes. Texas warehouses deploy automated systems for the picking and assembling of components, ensuring precision, speed, and consistency in the kitting phase.

Minimizing Waste and Enhancing Sustainability in Manufacturing:

Proper kitting contributes to waste reduction in multiple ways. Firstly, it helps avoid overstocking, which can lead to materials becoming obsolete or expiring. Secondly, it minimizes the risk of material damage or loss during storage or handling. Lastly, reduced errors and rework translate to less waste in the production process, contributing to overall sustainability.

Improved Workplace Organization:

Kitting promotes a clean and organized workplace. By having all necessary components pre-arranged and labeled, assembly personnel can maintain a clutter-free and efficient work environment. This also enhances safety, as workers are less likely to encounter misplaced or hazardous materials.

The Key Role of Proper Kitting in Successful Assembly Operations:

In conclusion, proper kitting is a fundamental element in optimizing assembly operations. It streamlines workflows, reduces errors, enhances productivity, and contributes to overall cost-effectiveness. Manufacturers who prioritize efficient kitting practices experience smoother production processes, improved product quality, and better resource utilization. By recognizing the importance of proper kitting and implementing best practices, businesses can stay competitive, respond to market demands effectively, and achieve success in their assembly operations.

Proper kitting is a linchpin in the success of assembly operations within Texas warehousing. From streamlining processes and enhancing accuracy to efficient resource utilization and meeting customer demands, the benefits of proper kitting are far-reaching. As warehouses in Houston, Dallas, and across Texas continue to embrace advancements in technology and best practices, the importance of proper kitting remains at the forefront of efforts to enhance efficiency and competitiveness in the dynamic world of logistics and warehousing.

For more information, feel free to get in touch with us. Our dedicated team is ready to assist you with any inquiries or details you may need. Whether you have questions about our products, or services, or want to discuss specific requirements for your projects, we are here to help.